Sustainability Trends in the Tire Industry: Insights from Black Donuts

Today, the green tire market is worth a remarkable $33.68 billion. But looking ahead to 2033, this market is set to skyrocket to an astonishing $85.79 billion (source). So, what’s driving this noteworthy growth? A few key factors are at play, and we’ll break down the top three: materials, tire plants, and recyclability.

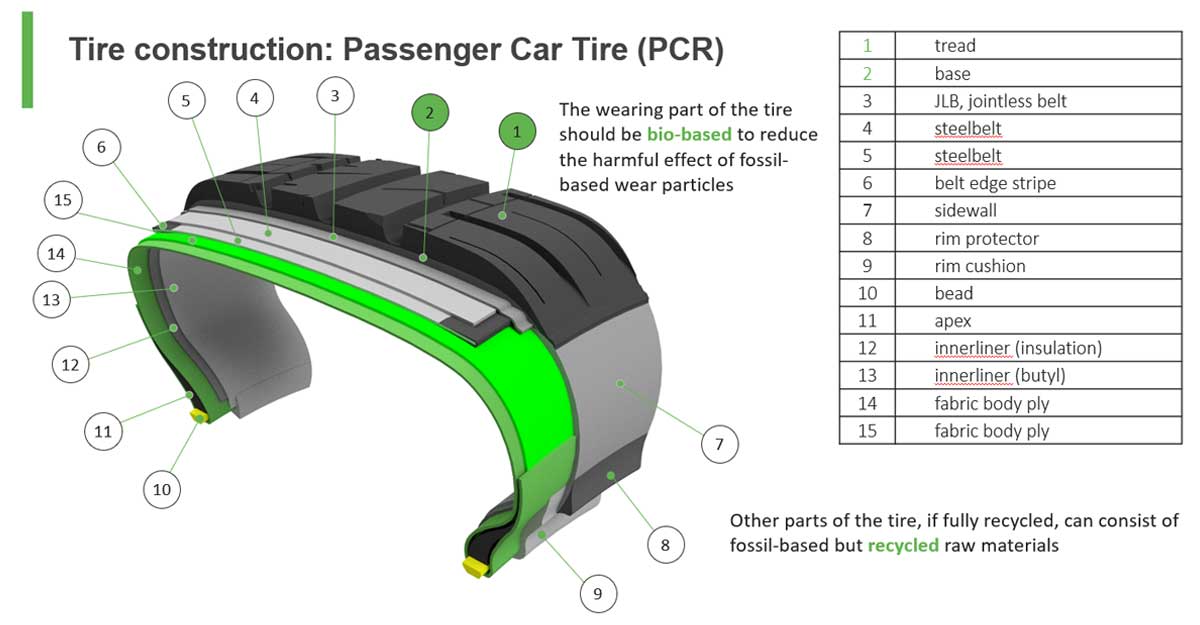

To start with, let’s talk about the composition of tires. Tires are mostly made from materials that originate from fossil-based raw materials. The issue is that these materials can break down over time, creating tiny particles that fall into the category of microplastics. It is a form of pollution called microplastic pollution. And that’s not great news for the environment.

Now, what exactly does this mean? Well, when we look at the weight of a typical tire, about 50-60% of it is made up of fossil-derived materials. These materials can break down over time, creating tiny particles that are a type of microplastic. Alarmingly, around 90% of tire wear particles consist of fossil-based materials.

This is significant because these particles can find their way into the environment. Tires release these microplastic particles, adding to the overall microplastic waste found in our oceans, accounting for more than 10% of the total.

Now, why does sustainability matter in the tire industry? Martti Päivinen, in charge of Quality and Risk Management at Black Donuts, explains that sustainability is crucial because it addresses the environmental impact of tire manufacturing and disposal. It’s easy to imagine the great possibilities of recycling old tires into eco-friendly materials for making new tires and other products. So, what is the solution?

According to Martti, the part of the tire that wears down should be made from bio-based raw materials to reduce the harmful effects of these fossil-based wear particles. If properly recycled, other parts of the tire can still contain fossil-based but recycled materials. This way, the end-of-life tire would be fully recycled.

Tires have a connection to microplastic pollution, which is a growing concern for our planet. By embracing sustainable practices, the tire industry can do its part to reduce these harmful effects and help create a cleaner world.

The significance of green tire plants

Tire manufacturing has long been associated with environmental concerns because it’s resource-intensive and energy-consuming. Are we considering how the energy is generated for the tire manufacturing process? Is biogas available instead of natural gas? How is the electricity generated for the tire plant? Can we utilize sustainable solutions? Are renewable sources available? Can we use solar power for some energy consumption?

The extraction of raw materials, like rubber and petroleum-based compounds, can harm the environment, and disposing of old tires often leads to waste management problems. Recognizing these challenges, the industry is actively searching for ways to reduce its environmental impact.

Circular Economy & Recyclability

A circular economy approach is central to sustainability initiatives. Companies are investing more in tire recycling and reusing programs, extending the lifespan of tires. This not only minimizes waste but also reduces the demand for new raw materials. A circular economy model is not only environmentally sound but also economically viable.

The tire industry is working hard to create tires that are better for the environment. Why? Because the world is changing, and what we want from the things we use is changing too. People like electric cars these days, and they want eco-friendly tires. So, what do these environmentally conscious audiences want? They want more sustainable tires that are made from natural or recycled materials. They also want tires that don’t release tiny, harmful particles or wear out quickly. These tires help cars use less fuel and emit fewer harmful gases like carbon dioxide. Also, rules and regulations are getting tougher. They’re making sure that tires don’t harm the environment. They’re also saying no to certain chemicals that used to be okay in tire production.

How are these trends impacting BDE’s business, and what strategies is BDE adopting to stay ahead?

Martti Päivinen shares that one of the key insights from Black Donuts is the importance of using bio-based raw materials in tire production. Our company has been proactive in sourcing sustainable materials that minimize environmental harm. We can significantly reduce reliance on non-renewable and harmful materials by incorporating renewable and recycled resources into our customer’s production process. This shift not only reduces the carbon footprint but also contributes to resource conservation.

Therefore, the green raw material solution is our first step in transforming the conservative tire industry into a more sustainable domain. We are working with solutions where we can replace 100% of fossil-based carbon black with biobased raw material in tires. We aim to use only biobased and recycled raw materials in tire production by 2030. It is good to mention that we personally source essential sustainable materials for client projects. Our criteria are quality, price, reliability, and location.

According to Martti, it is essential to mention that the shift towards more environmentally friendly tires should be a gradual process. Think of it as transitioning your diet from one that’s gluten-rich to a gluten-free one – you need to plan and test new recipes to ensure your body remains nourished and healthy. Similarly, this principle applies to the tire industry; technical properties and safety have to be ensured with new raw materials.

At Black Donuts, we’re all about using advanced methods to be more eco-friendly. By adopting cutting-edge processes, we have improved energy efficiency, reduced waste generation, and implemented pollution control measures. These advancements not only benefit the environment but also save money, making sustainability a win-win. We also use less energy and add eco-friendly power sources like solar panels. Plus, we’re reducing waste by recycling within the tire plant.

Collaboration is vital, too, according to Martti. We have partnered with environmental organizations and research institutions to share knowledge and develop sustainable practices.

We also design tire plants that meet European environmental, health, and safety standards. This way, by choosing greenfield tire plant solutions, customers can be confident that they contribute to a greener future without compromising quality or productivity.

Future Outlook

As we look to the future, sustainability will continue to be a driving force in the tire industry. Companies can encourage other tire manufacturers to follow their example by demonstrating that sustainability is achievable and profitable. As more companies adopt eco-friendly practices, the tire industry will move towards a greener and more sustainable future.

The future of sustainability in the tire industry is promising. As consumer awareness and demand for eco-friendly products increase, tire manufacturers will be more motivated to adopt sustainable practices.

BDE envisions a future where sustainability is not just a buzzword but a standard practice throughout the industry. BDE company has ambitious plans. The company aims to continue innovating and improving its sustainability efforts. This includes further research into sustainable materials, exploring new manufacturing technologies, and expanding its circular economy initiatives. BDE is also actively engaging with regulatory authorities and advocating for more sustainable practices within the industry. Perhaps the most significant contribution from Black Donuts to tire manufacturers is to inspire change towards more sustainable products.

Do you have inquiries about greenfield, brownfield, or tire development projects? Don’t hesitate to contact us today and unlock the solutions you seek. Explore how we can support you in embracing the future of tire innovation.