Improving Tire Factory Efficiency With MES Systems: Why It Matters

Black Donuts Inc. is a full-service technology house that offers end-to-end turnkey solutions for designing, building, supervising and running a smart tire plant with maximized productivity and best-in-class production. Our company has led the development of over 50 tire plants worldwide and 1000+ tire product designs. We are also the #1 tire technology expert and a leading R&D tire specialist. Lately, we have received a lot of requests from our business partners regarding the MES (Manufacturing Execution System), what it is and how it improves tire production. Also, tire manufacturers are keen to know not only what benefits they can get from investing in MES but also if MES can help them make more money. This article will explain the basics of MES and why it’s essential in today’s tire factories.

What is MES?

MES, or Manufacturing Execution System, is a computerized solution used in manufacturing to track and closely monitor tire factory operations, everything from transforming raw materials to finished goods. One can easily say that MES is a tire factory’s helpful assistant, ensuring smooth communication and operation between departments. When something goes off track, just like a detective, MES figures out what went wrong.

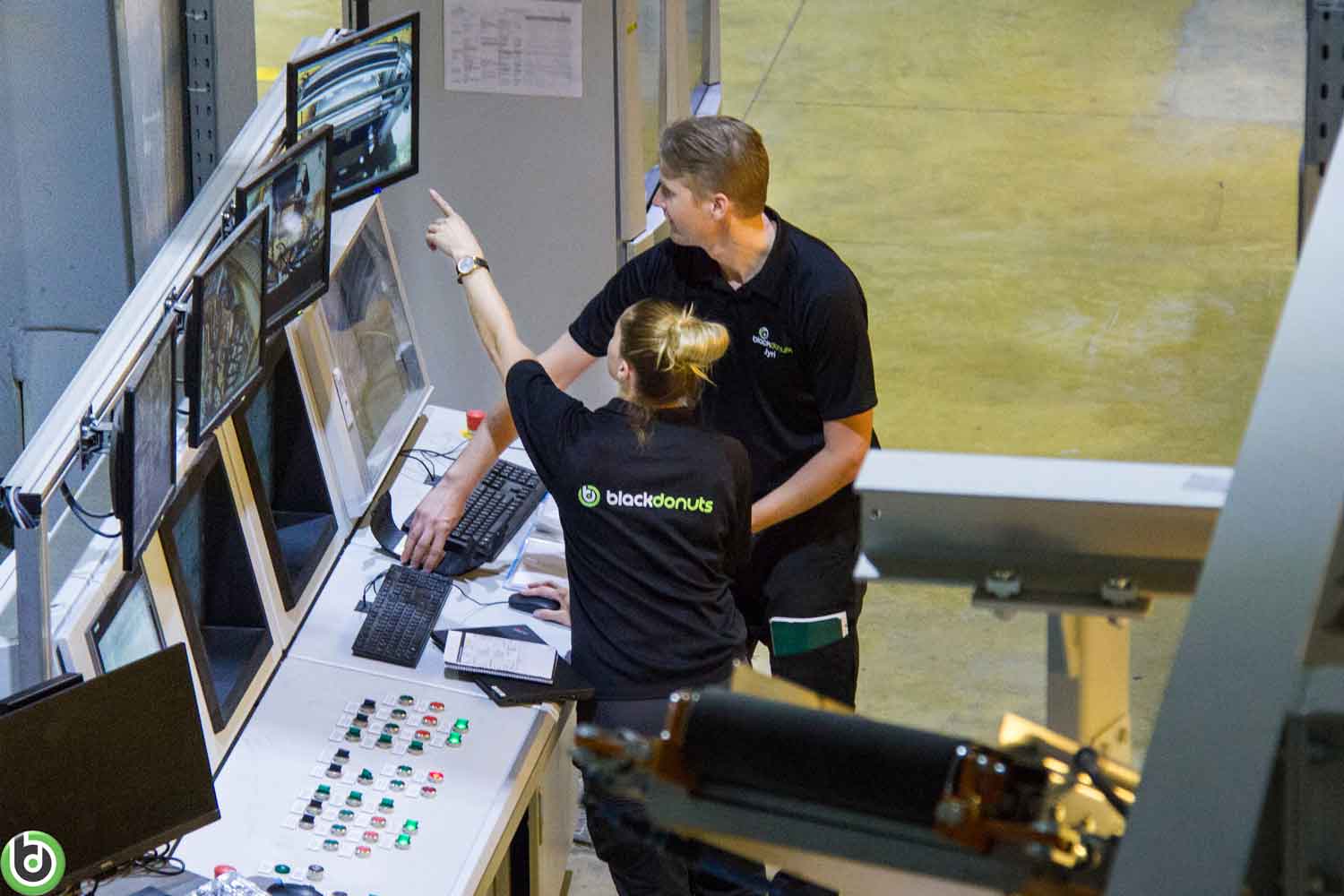

Pekka Vaittinen, Director of Automation and Solutions at Black Donuts Inc., emphasizes that MES’s main task is production efficiency in capacity and quality trace and to monitor ‘super-fast’ the root causes of any manufacturing defect. The advantages are faster production, higher quality, and fewer errors.

The video below illustrates how Black Donuts assisted IRIS Tyres in planning their Energy Management System (EMS).

So, simply put, MES watches the factory’s tire-making process like a smart computer system, ensuring everything works well. It monitors, controls, and connects all stages of the tire production process, thus helping manufacturing decision-makers understand how current conditions on the plant floor can be optimized to improve production output.

Using MES and EMS for Eco-Friendly Tire Manufacturing

Challenges and Solutions in Utility Consumption Tracking

Reducing Waste and Improving Quality with MES: A Practical Example

Based on Black Donuts’ substantial experience spanning over a decade, the primary advantages include improving production, reducing waste, and improving tire quality. Here’s a concrete example.

We assisted tire manufacturers through MES implementation and showed the client how to effectively identify and resolve manufacturing and quality issues, mistakes and defects. By analyzing and “deep drilling” into the root causes of defects, they elevated product quality and reduced defects and waste to a minimum. The MES solutions also helped the clients to:

- Minimize waste caused by human errors.

- Gain operational visibility to optimize production setup and adjustment.

- Identify and address daily bottlenecks, such as additional tools or tooling to boost output and reduce idle time.

- Maximize machine capacity utilization while avoiding planning errors.

- Monitor production alarms and focus on maintaining high Overall Equipment Effectiveness (OEE) through timely maintenance.

By closely tracking production workflows, our clients better understood their operations. This insight enabled the identification of blockage, process inefficiencies, and areas where resources can be allocated more effectively. They could quickly see what was slowing them down and where they were making mistakes. This made them make more tires, save money, and make better tires.

Trends and Innovations

MES systems modernize tire factories, enhance communication, and promote sustainability. As the tire industry evolves, embracing MES systems and innovative utility consumption approaches is crucial for success.

Trends include AI, IoT, and sustainability initiatives, driving innovations in utility consumption management. Data security is a priority, ensuring reliable hardware and network architecture.

At Black Donuts, we expect increased use of AI, machine learning, and IoT for predictive analytics, and a focus on renewable energy and circular economy principles. IoT adoption will expand, enhancing real-time data collection. Cybersecurity investments are essential to safeguard energy data. IoT-driven real-time analysis provides precise energy consumption insights, eliminating wasteful practices and promoting eco-friendliness. Sustainability initiatives will drive innovations, emphasizing renewable energy sources and circular economy principles in utility consumption management.

MES is vital in tire plants due to evolving industry trends and diversified tire manufacturing. It enables cost-saving measures and supports informed decision-making. Black Donuts’ MES solutions offer improved efficiency, waste reduction, and quality control. We assist in identifying and resolving manufacturing defects, optimizing production setup, addressing bottlenecks, and maintaining high Overall Equipment Effectiveness (OEE). Additionally, our approach involves using reliable hardware, considering its lifespan, malware possibilities, and collaborating with world-class experts to ensure data security. We also plan network architecture to contain potential breaches within restricted areas, addressing various data security and compliance aspects.

Have a question? Contact us for MES setup inquiries.

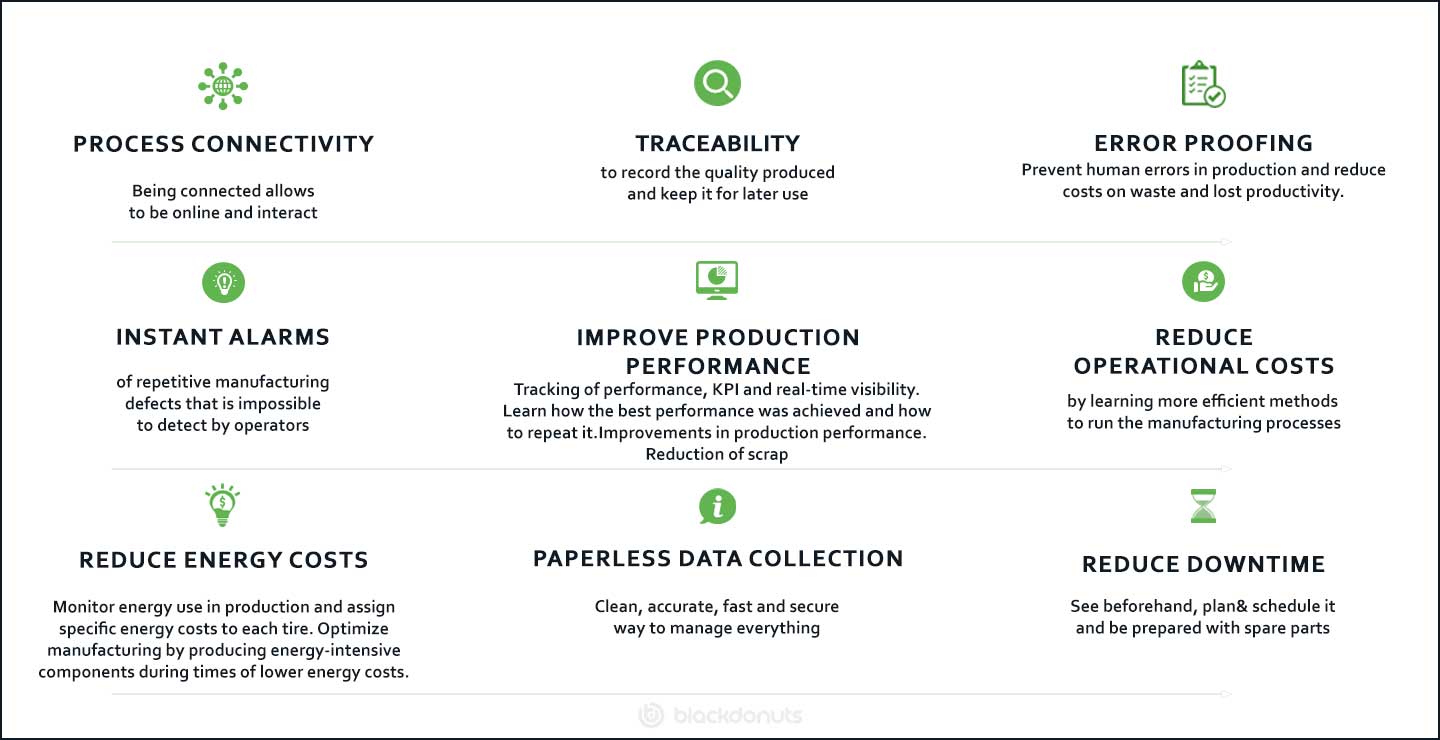

Benefits of MES