Tailored solutions

Tire Design and Tire Construction Across Multiple Product Categories

At Black Donuts Inc., we design high-quality tires tailored to meet demanding standards for performance, durability, and safety. Our in-house design tools simplify the tire construction process, cutting development time and enhancing efficiency. Typical tire construction deliverables include:

- Mould cavity design drawing

- Cured tire layout drawing

- Cured tire specifications

- Green tire specifications

We have reliable solutions for all winter tire specs, ensuring great performance in tough, cold conditions. Our AT (all-terrain) & MT (mud-terrain) tire specifications are optimized for durability, designed to meet the needs of the USA market. We also provide heavy-duty solutions for extreme environments, like desert tires and tires for emerging markets. For EV (electric vehicle) tires, we offer solutions that enhance load-carrying capacity while optimizing hysteresis and heat build-up.

Precision Tire Solutions

We precisely predict tread and sidewall profiles using advanced simulation technology, significantly reducing trial and error loops. This streamlines the manufacturing process, minimizing the need for extensive test tire runs and industrialization efforts. Our skilled R&D team uses advanced CAE tools to optimize tire performance from the earliest design stages. The result?

Faster goal achievement with fewer prototypes, saving time and resources without compromising on quality.

From selecting premium materials to final curing, we integrate precision, expertise, and cutting-edge technology into every step. Whether reducing emissions, improving rolling resistance, or designing lighter tires without sacrificing performance, our innovative solutions drive meaningful impact. With a focus on quality and sustainability, we ensure responsible manufacturing practices that help you meet regulatory requirements and create tires that make a difference.

Tire Construction Development Process

When developing a completely new tire, we use the latest rubber compounding technology, FEA-simulated tire structure, and tire cavity. Based on their properties, we design a tread pattern, achieving the best possible combination to reach the set performance targets and customer needs. The tire’s market-appealing looks come with a proven performance level, effective manufacturing, and well-selected, sustainable materials. We audit customers’ technical capability of tire building and the materials they are currently using to develop new tire constructions that best suit their purposes. This may include introducing totally new materials or combining existing materials.

- Competitor analysis

– cross-section analysis

– materials and measurements - Customer capability auditing

- Selecting the best materials for customer needs

- Simulation tools for footprint, structural durability, rolling resistance

- Designing tire cavity and structural components

From precise cavity and construction design to optimized material distribution, we ensure every detail works seamlessly with your manufacturing process

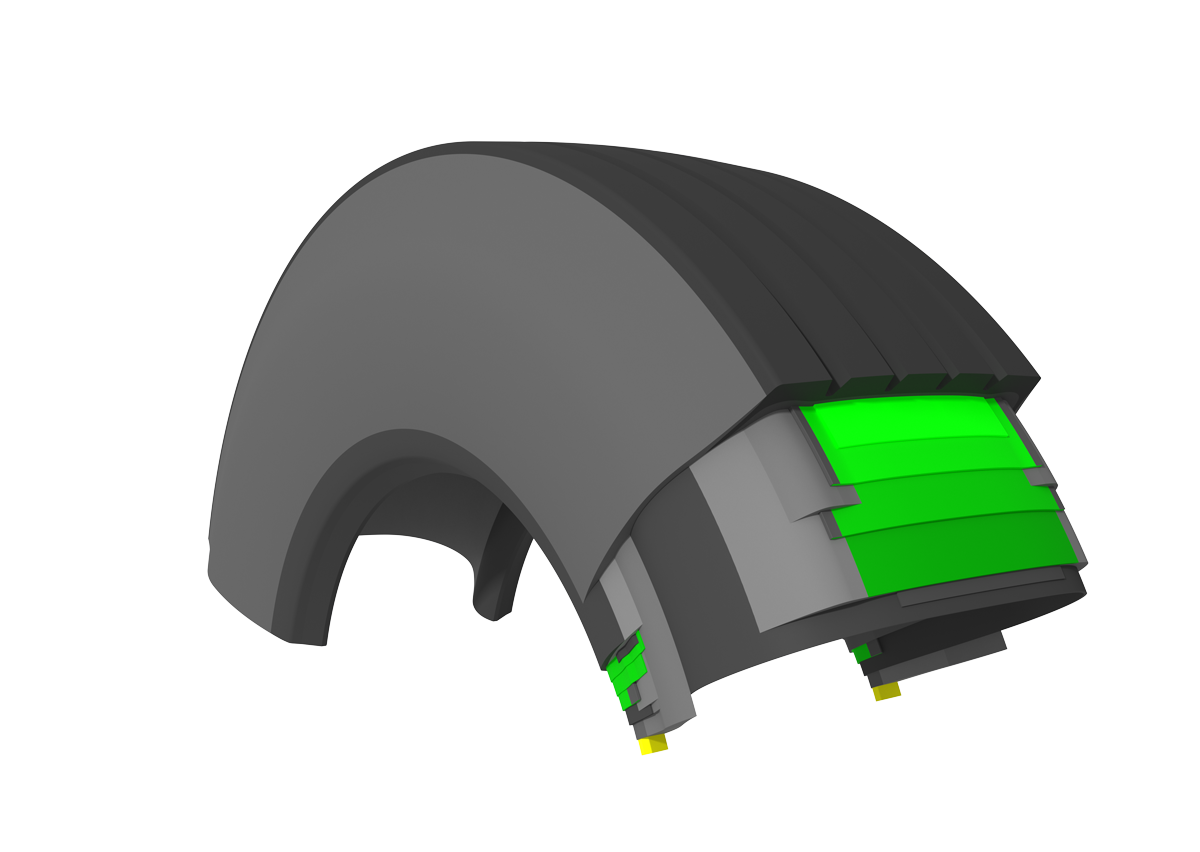

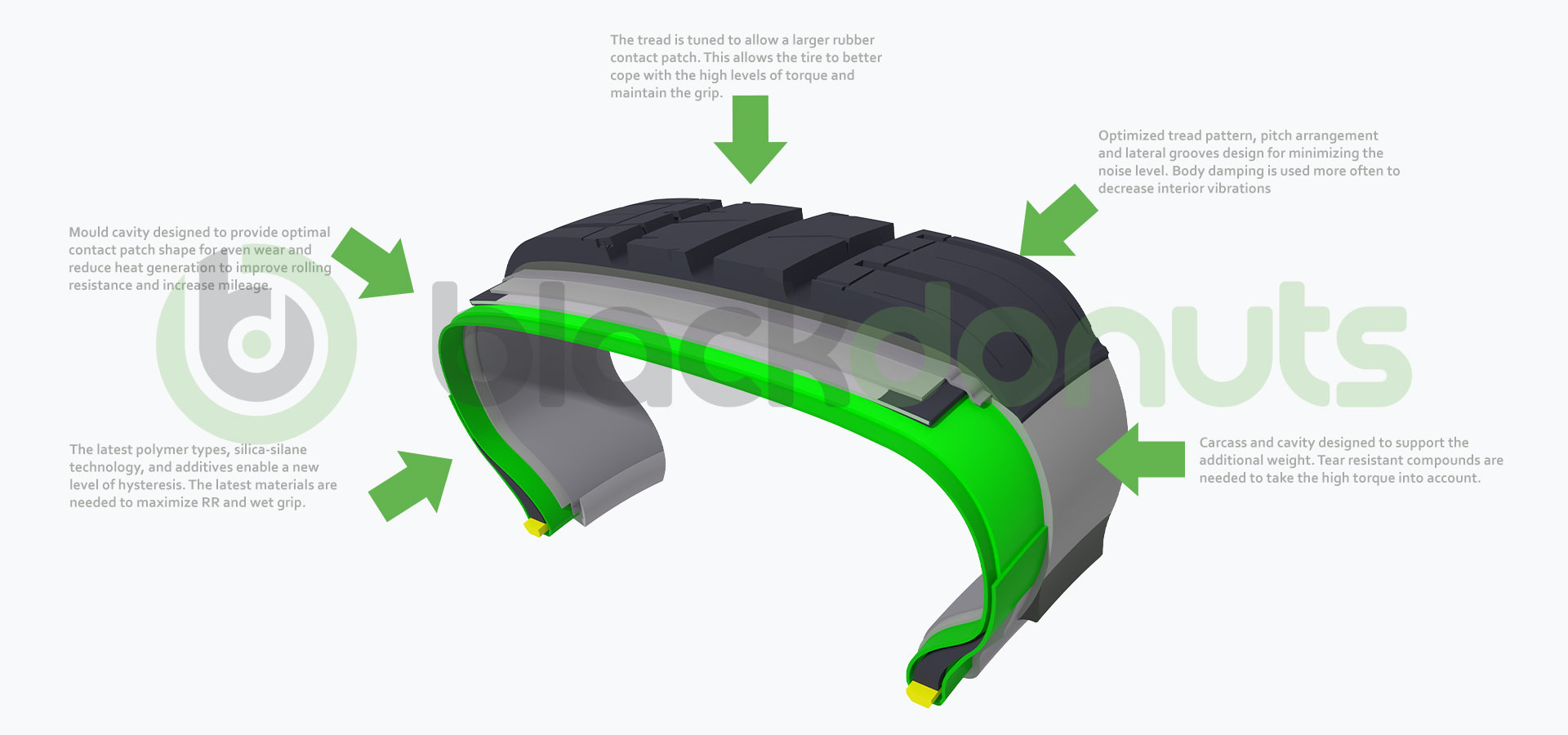

EV Tire Specific Features

Why Choose Us?

Mould cavity design +

The mould cavity is designed to provide an optimal contact patch shape for even wear, reduce heat generation, improve rolling resistance, and increase mileage.

Enhanced tread design +

The tread is tuned to allow a larger rubber contact patch, enabling the tire to better cope with high levels of torque while maintaining grip.

Noise & vibration reduction +

The optimized tread pattern, pitch arrangement, and lateral groove design work together to minimize noise levels, while body damping is used more frequently to reduce interior vibrations.

Better Grip and Efficiency +

Balanced tire stiffness and contact patch designing can be achieved remarkable steps in increasing traction properties and energy efficiency of tires.

Durable design +

The carcass and cavity are designed to support the additional weight, while tear-resistant compounds are needed to handle high torque.

Tailored Solutions +

With decades of experience, we deliver exceptional tire design and construction results. Our processes are customized to meet your unique needs, from material selection to final assembly.

Detailed specifications +

We support your evolving needs, enabling future growth and long-term collaboration and provide detailed specifications to meet your performance, durability, and safety standards.

Unmatched Quality +

We use cutting-edge equipment and methods to ensure optimal performance and durability. Rigorous testing and inspections guarantee our products exceed industry standards.