Tailored Compounds for Safer, More Efficient, and Sustainable Tires

The tread compound is the most critical tire component for ensuring safety, reducing emissions, and enhancing performance. That’s why BD devotes significant research efforts to developing proven, ready-to-use solutions tailored to meet customers’ diverse needs and applications for tread compounds.

For PCR, we focus for example on low surface area fillers, advanced silica-silane coupling, low-Tg S-SBR grades, and modern raw materials like liquid polymers and resins.

For TBR, we specialize for example in high abrasion resistance compounds with balanced features and develop high silica-level compounds to improve rolling resistance (RR) and wet performance without sacrificing mileage. The most typical deliverables are:

- Compound recipe formulation

- Test result summaries

- Mixing recipe for lab/plant mixer

We offer hands-on support in material selection, compound formulation, and mixing technology for customers transitioning to renewable and recycled raw materials.

Comprehensive Compounding Support for Every Tire Application

Innovative Compounding Solutions

BD provides comprehensive support in developing and sourcing raw materials, integrating renewable and bio-based options into tire compounds. From the early stages of the supply chain to understanding the chemical interactions of materials, we focus on key areas to enhance both sustainability and tire performance:

- Bio-based fillers

- Bio-based oils & resins

- Bio-based polymers

- Recycled carbon black

By carefully evaluating these materials, BD ensures their compatibility and effectiveness, driving innovation while promoting sustainability in tire production. We offer comprehensive compounding support for all BD tire applications, covering the entire compound lineup, including the treads and every aspect of your tire formulations.

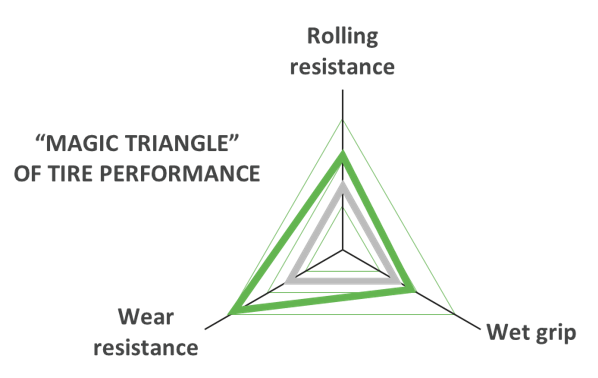

The Magic Triangle

The three fundamental functions of tires, commonly called the ‘Magic Triangle’ in the industry, are rolling resistance, wet grip, and wear resistance. Achieving optimal performance across all three functions simultaneously is challenging. At Black Donuts, we achieve this with:

Playing and largering the Magic Triangle by

- Innovated compound innovations

- Advanced mixing techniques

- Latest, most modern raw materials

Mixing Technology

- Formulation optimization for mixer environment, creating best practices & SOP for mixer lines

- On-site support for compound industrializations

- Compound development for various applications and performance criteria for PCR, TBR, and OTR tires

- RM cost optimization for tire compounds and materials

We fully utilize all the advantages of the customer’s mixer line, whether it is the most modern tandem mixer, intermesh, or tangential one.

Research Projects

Our extensive collaboration and joint activities among raw material suppliers ensure the best testing and evaluation of the latest raw materials for our customers’ compound concepts.

Example projects for our clients are:

- Substituting 6PPD usage in tires

- Extensive studying and testing of alternative substituting materials

- Verifying the compound performance

- Tire particle emissions: reducing and making emissions less harmful

- Understanding of the basic mechanism of tire wear and particle emissions

- New solutions to influence and spectrum of particle size deviation

- Introduction of less harmful and bio-based raw materials

- Tire crack growth understanding and feature improving

- Low RR & high abrasion resistance compounds for EVs

- Compound tailoring for an enhanced level of bio-based RM’s

- Processability improvement of compounds in lab scale

- Testing new RM grade for proven tire compounds and getting an understanding of the real functionality in tire

- Longer-lasting tread compounds off-road applications