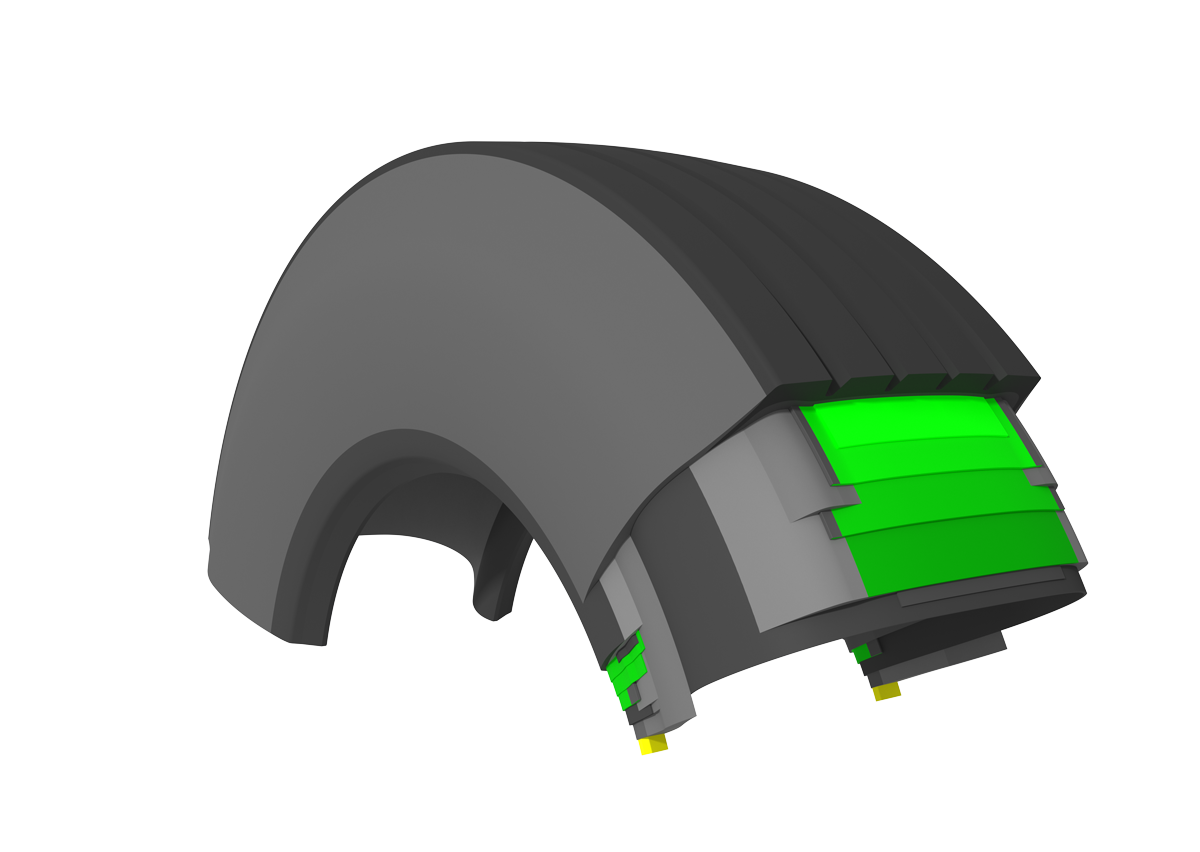

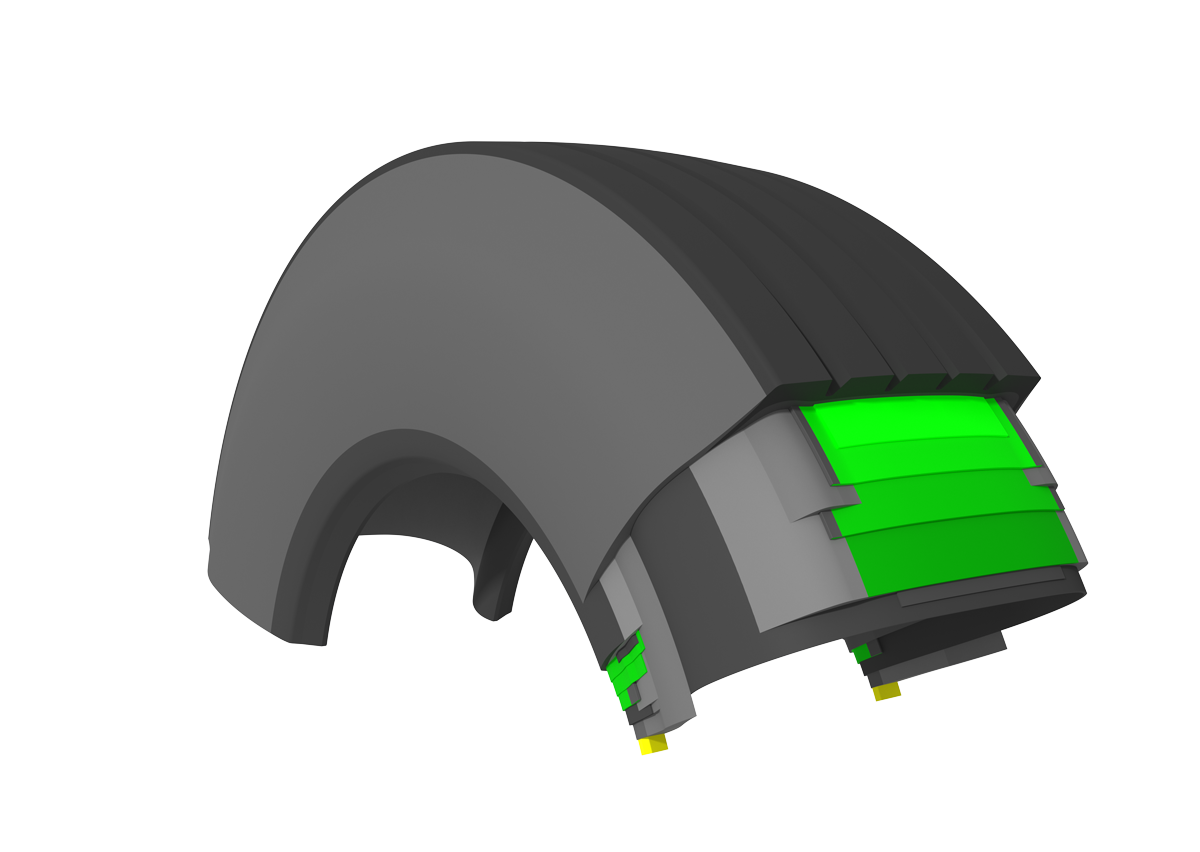

TBR Tires with OPT & OCP Technology

At the core of our expertise lies the optimization of tire materials, design, and processability—three essential factors for creating high-performance TBR tires. We are committed to ensuring exceptional durability, efficiency, and performance.

Our OPT Tech (Optimizing Body Ply Tension) and OCP Tech (Optimizing Contact Pressure Distribution) concepts guide us in achieving the ideal tire design. Together, these techniques allow us to deliver a tire that maximizes longevity, performance, and safety tailored to the specific material properties. We provide comprehensive design solutions tailored to your specifications including:

- Mould cavity design drawing

- Cured tire layout drawing

- Cured tire specifications

- Tread pattern design

- Sidewall pattern design

- 3D tread pattern CAD drawing

- Mould drawings

TBR construction design process

Material Selection +

Selecting the right materials (compounds and reinforcements) is crucial for tire’s overall structure and performance. Advances in material science enable us to choose compounds and reinforcements that meet durability and performance targets while optimizing cost and sustainability. As the industry moves toward eco friendly solutions, we ensure a balanced approach that delivers durability, efficiency, and environmental responsibility.

Design Optimization +

A well-optimized tire construction maximizes performance and longevity. We implement two key design technologies to enhance structural integrity and wear resistance: OPT Tech and OCP Tech. By precisely adjusting the body ply tension, we ensure optimal structural strength and flexibility, enhancing durability and performance. Simultaneously, our OCP Tech ensures an even distribution of contact pressure, optimizing traction, wear resistance, and overall handling.

Processability +

Designing for processability is essential to ensure that the tire can be efficiently manufactured. By aligning designs with machine capabilities, process limitations, and standardization requirements, we create practical and repeatable tire designs. Our designs are optimized for manufacturability, ensuring consistency, cost efficiency, and seamless scalability.

Validation +

FEA plays a vital role in design validation, allowing us to simulate real-world performance with precision. Our expertise in FEA ensures accurate data interpretation and continuous refinement, leading to more precise predictions and improved final designs.

Final Design +

Using the most reliable FEA results, we finalize the tire design with a focus on optimal performance, durability, and manufacturability, delivering a high-quality, cost-effective product.

Tread Design

Tailored TBR Tread Design Solutions

The tread design of high-strain TBR tires has evolved significantly to meet the demanding requirements for performance and durability. With our deep understanding of the complexities, limitations, and critical areas for optimization, we provide precise solutions to fine-tune tread designs, ensuring they meet or exceed performance and durability targets.

Key areas of tread design-Concept development

Functional Elements +

Tread pattern design focuses on functional elements tailored to terrain type (regional, mixed, or long-haul) and fitment category (steer/all-position, drive, or trailer). Achieving the right balance of rubber mass in the right areas significantly enhances tire mileage and helps prevent uneven wear. Our expertise ensures optimal performance.

Aesthetic Elements +

We incorporate visually appealing, temporary aesthetic elements that not only reflect our brand’s signature but also add a distinctive touch to the product’s overall design. These elements connect with our design philosophy, making each product unique and memorable.

Validation +

To reduce corrections and maximize efficiency, we predict the final output early. Using advanced tools and FEA (Finite Element Analysis) expertise, we simulate tread deformation, footprint, surface frictional energy, pattern stiffness, and noise. This rigorous process ensures the design is thoroughly vetted before moving forward.

Final Design +

The final step involves refining the tread pattern based on simulation findings. Every observation is addressed to ensure the design is optimized for mold manufacturing. The result is a perfectly balanced and validated tread design that delivers both performance and aesthetic excellence.

Why Choose Us?

Advanced Material Selection +

We help you make smart material choices that balance performance, cost, and sustainability.

Cutting-edge Design Technologies +

Our OPT and OCP Techs deliver optimal design solutions that enhance durability and performance.

Processable Designs +

We ensure that all tire designs are efficient and cost-effective for manufacturing.

FEA Expertise

Our deep understanding of FEA allows us to interpret results accurately and deliver superior tire designs.

Optimizing the Body Ply Tension (OPT Tech)

In tire design, the body ply refers to the layers of fabric inside the tire that provide strength and shape. The tension in these plies must be carefully optimized to ensure the tire maintains the proper structural integrity under load while being flexible enough to handle road conditions. OPT Tech focuses on adjusting this tension to maximize the tire’s strength, stability, and performance over its lifetime. It ensures the tire performs well in handling, comfort, and durability while minimizing wear and deformation.

Optimizing Contact Pressure Distribution (OCP Tech)

This refers to how the tire’s footprint (the area that touches the road) interacts with the road surface. The pressure distribution across this area must be as evenly as possible to avoid premature wear, improve grip, and enhance fuel efficiency. OCP Tech is fine-tuning the tire design so that the pressure is evenly spread across the contact patch. This allows the tire to provide better traction, longer life, and more consistent performance.

Together, OPT Tech and OCP Tech help create a tire design that delivers the best combination of durability and performance by focusing on the internal structure and how the tire interacts with the road. This is done with the material properties in mind, ensuring that the tire performs well and lasts longer under various driving conditions.