Complete engineering and R&D

Premium tires for PCR, TBR, OTR, AGRI, and two-wheelers

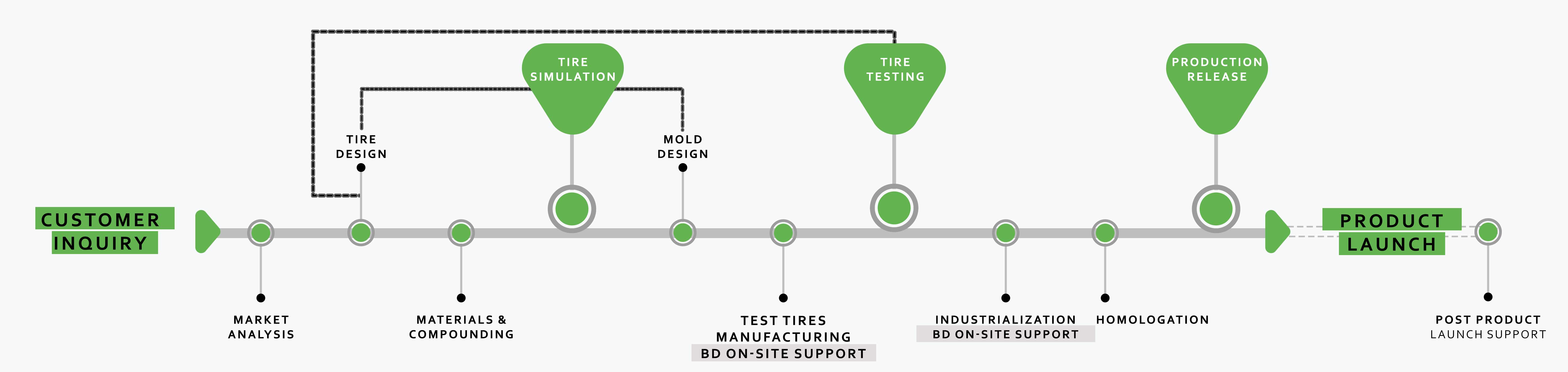

At Black Donuts, we specialize in tire development from concept to production. From material selection to tread and mold design, and industrializing production, we ensure every tire meets the desired performance and profitability targets.

As a leading engineering and R&D hub, we offer turnkey solutions that empower tire manufacturers to excel in a competitive market. Our innovative, fit-for-purpose technology sets the standard, allowing our tires to rival Tier-1 brands in performance while being among the greenest on the market. We produce a wide range of premium tires, including summer, winter and all-season PCR/SUV, TBR, and OTR for various applications, AGRI, and two-wheeler tires. Our services include:

Whether you’re targeting niche markets or expanding into new territories—from Europe to the USA or Africa—we deliver products designed to meet the specific demands of each market.

Product Development

When developing a new tire, we utilize the latest advancements in rubber compounding technology and FEA-simulated designs for patterns, tire structures and cavities. Using these insights, we design a tread pattern that delivers the optimal balance to meet performance targets and customer needs. The result is a tire that combines market-appealing aesthetics with proven performance, efficient manufacturing processes, and carefully chosen, sustainable materials. By leveraging advanced software to automate and verify design calculations, we significantly reduce development time without compromising on quality or precision.

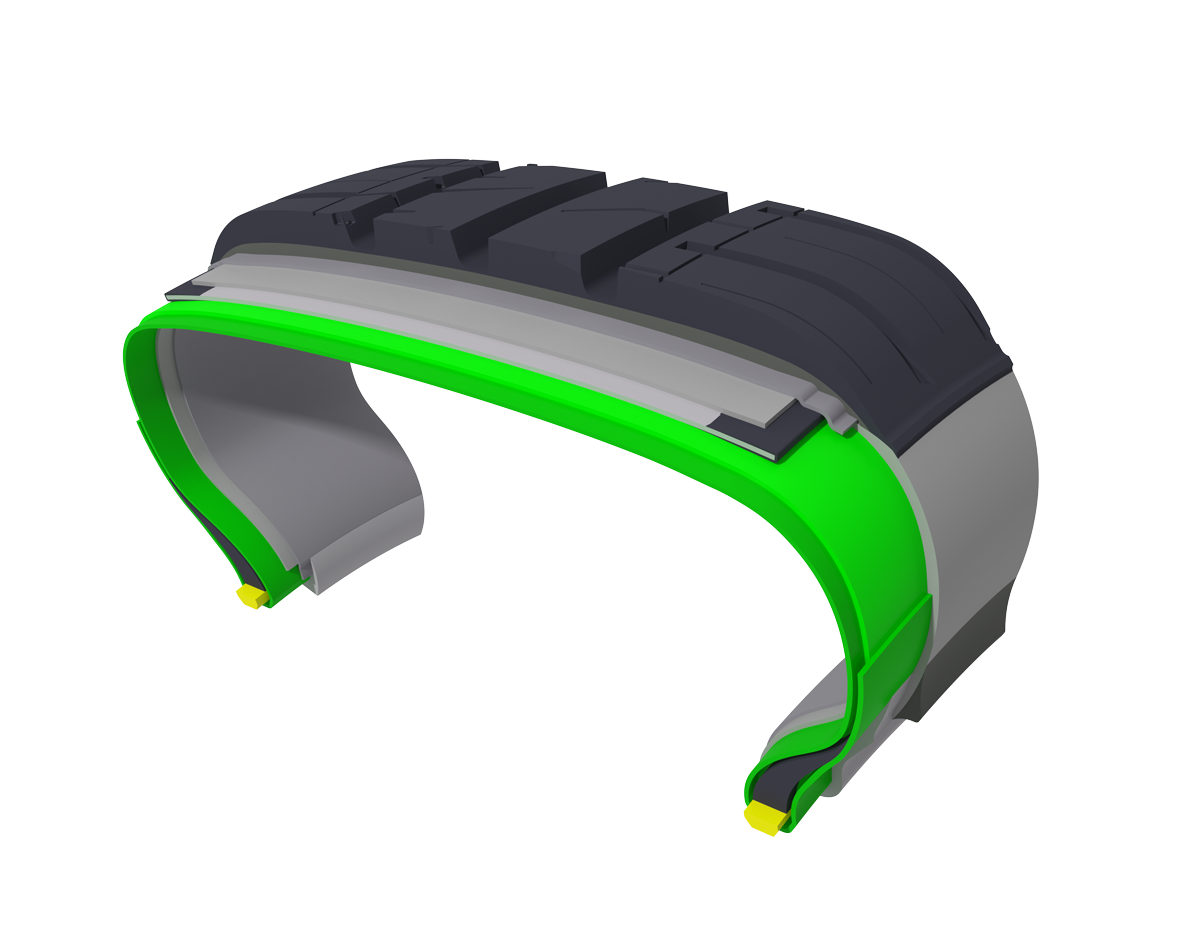

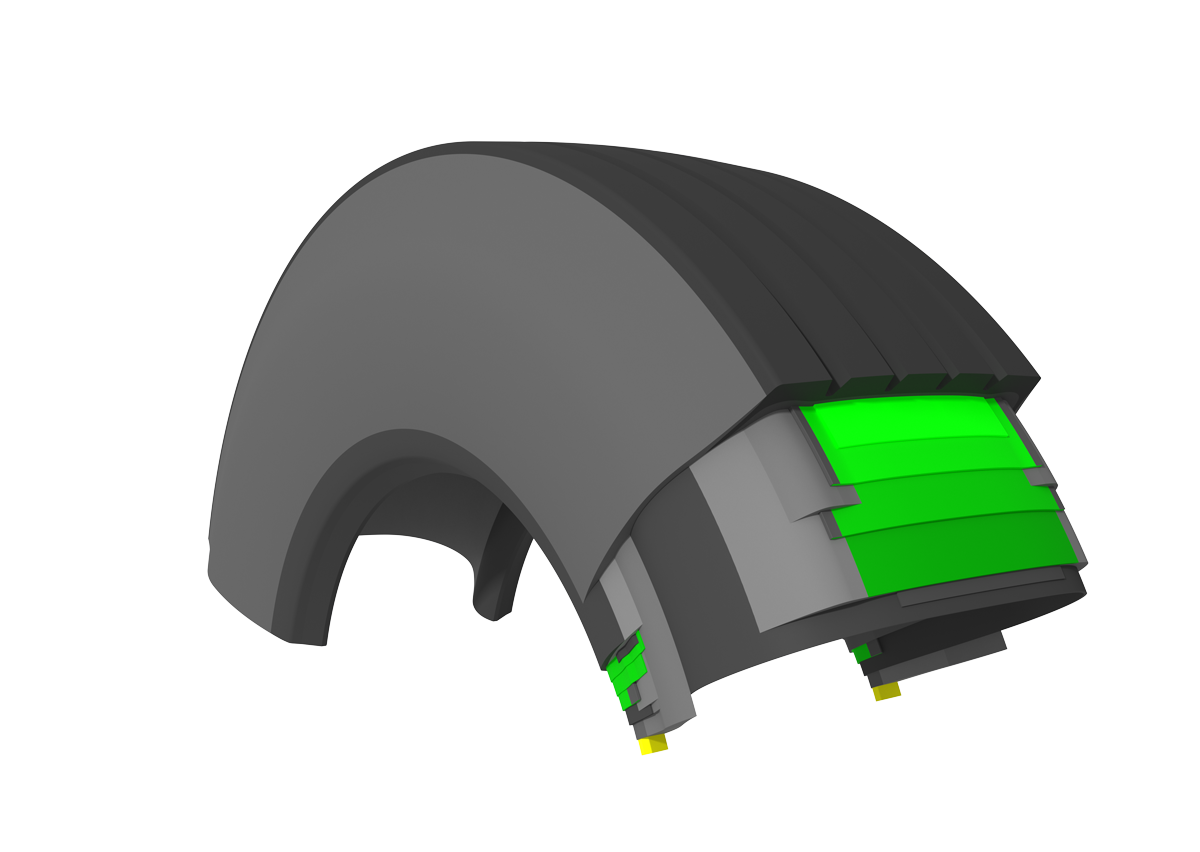

Tire Construction: PCR (left) and TBR (right)

New Tire Development Services

Benchmarking +

By analyzing tire markets and reference products, we can set development goals, profitability targets, and define product and brand positioning to ensure that the new product meets market expectations. This also helps our customers clarify how they want to position their products within the tire market.

Compounding and material R&D +

We audit customers’ technical capabilities in mixing and the materials they use to develop optimal compounds for their needs. We offer proven, ready-made solutions for PCR and TBR tread compounds, tailored to specific applications. Additionally, we are ready to develop unique breakthrough solutions, which may include introducing new materials or refining existing ones. Compound recipes, material specifications, and mixing programs are part of the standard delivery package.

Tire construction development +

We audit customers’ technical capabilities in tire building and the materials they are currently using to develop new tire constructions that best suit their needs. Tire cavities and specification are then developed to meet set targets while considering processability. The designs benefit from the wide-ranging experience of the team and the latest technology available in BD’s FEA capabilities. Mold cavities, cured tire layouts, and manufacturing specifications are part of the standard delivery package.

Tread pattern development +

Tread pattern development combines both aesthetic and technical aspects into a high-performing product that maximizes the benefits of our material and tire construction development work. While maximum safety is our primary goal, we also consider and fine-tune all tire performance properties, as well as the effectiveness and reliability of tire manufacturing.

Mold design +

We provide a complete documentation package, including rendered images of the product, a 3D model, and 2D drawings.

Size range extension +

Our in-house developed design tools enable an extremely efficient way to produce additional sizes with high precision and attention to detail. Thanks to these tools and our professional team, consistent performance across the product range is achieved. A typical delivery includes mold documentation, tire construction designs, and tire manufacturing specifications.

Product Line Extension

Tire pattern

- BDE can design the required amount of sizes for range extension.

- BDE has a parametric model for the design process, ensuring efficiency and precision.

This approach allows for the production of all additional sizes with exceptional attention to detail.

Cavity & Construction

- Optimal result are achieved when cavity and construction are developed simultaneously.

The process includes high modularity, 2d layouts, green profiles, and more for a seamless design.

Sidewall

- If necessary, BDE can handle sidewall designs throughout the product range.

Constant performance through the product range