FEAtire simulation

Tailored End-To-End FEA Solutions For Advanced Tire Simulation

At Black Donuts, we offer comprehensive end-to-end FEA support, covering everything from model development to post-analysis recommendations. Our expertise empowers tire designers with valuable insights to optimize tire performance, reduce development cycle time and costs, enhance safety and efficiency, and drive innovative solutions. With deep technical expertise and a commitment to sustainability, we help clients achieve their goals faster and smarter. Key benefits of our solutions include:

- Assisting designers in developing robust, optimized, and sustainable products with precision.

- Identifying failure causes to prevent costly downtime or recalls.

- Enhancing safety by assessing risks and ensuring reliability under diverse conditions.

In addition, we offer a variety of customized training programs designed to accelerate the learning curve and equip both beginners and experienced engineers with essential skills to enhance their expertise and expand their competencies.

Our customized FEA simulation services cater to tire manufacturers, automotive OEMs, and other industry stakeholders.

By simulating tire behavior under stress, pressure, and road dynamics, our expert engineers optimize tire design, material selection, and overall performance.

This process reduces development costs, shortens time-to-market, and minimizes reliance on physical testing—supporting a greener approach to innovation.

With FEA, potential issues are identified and resolved early, ensuring precise solutions for more reliable, eco-friendly tires.

FEA Simulation Capabilities

Static and Dynamic Analysis

Conduct simulations for static loading, inflation, and steady-state rolling dynamics.

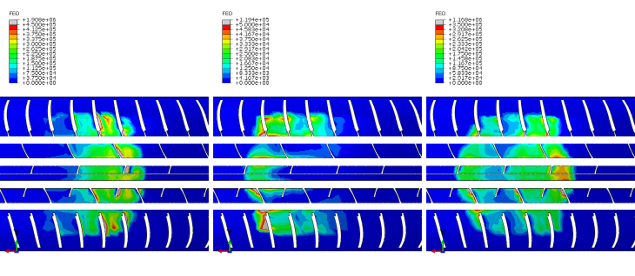

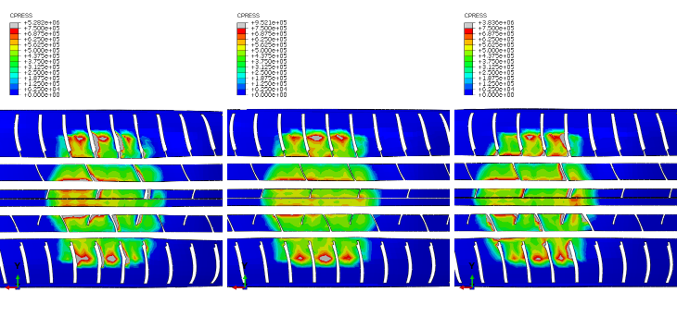

Tread Contact Analysis

Evaluate tire-road interaction, including stiffness, grip, and wear pattern uniformity under various conditions.

Thermal Analysis

Assess heat generation due to rolling resistance, tread deformation, bead area deformation, and internal friction for high-speed or heavy-load applications.

Durability Analysis

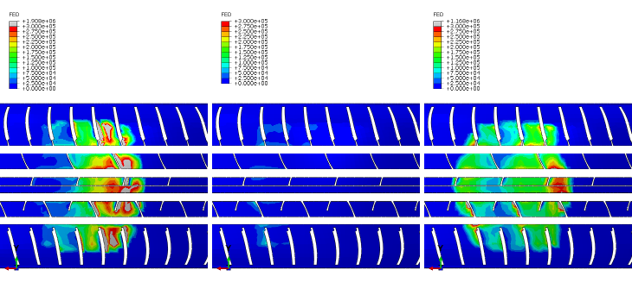

To assess tire longevity, simulate long-term wear, predict failure modes, and identify potential failure locations.

Rolling Resistance

Analyze the contribution of different components and design parameters to reduce rolling resistance, thereby improving fuel efficiency.

Vehicle Handling

Examine tire behavior during braking, traction, and emergency handling scenarios.

Why Black Donuts?

Black Donuts offers a total solution package with tire finite element analysis services, including detailed simulations and assessments of performance, durability, and safety tailored to tire manufacturers, automotive OEMs, and other industry stakeholders.

Black Donuts Finite Element Analysis Capabilities

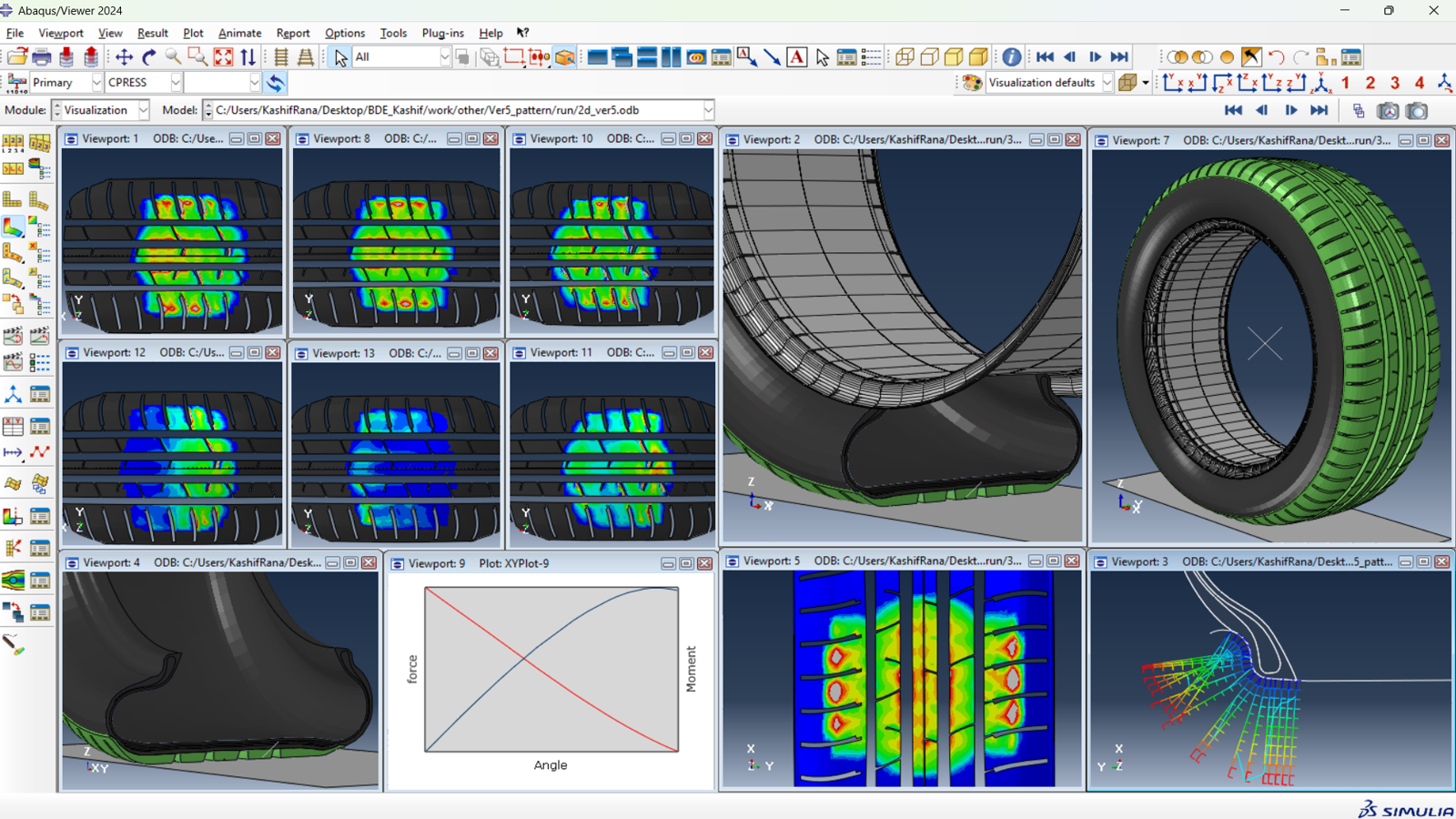

Finite Element Analysis (FEA) plays a crucial role in tire design and failure analysis, making it an essential tool for most tire manufacturers. At Black Donuts, we’ve made significant investments to develop a cutting-edge tire FEA setup, empowering designers and engineers to streamline their daily workflows. This enables the creation of more reliable designs and specifications, ready for the trial tire phase, and better end results can be achieved faster. With our expanded simulation capabilities, Black Donuts is now proud to offer FEA services to external customers.

- 3d loading

- Dynamic behaviour

- Tire wear estimation

- Force and Moment Characteristics (F&M)

- Tire Stiffness (Lateral, Longitudinal, Radial & Torsional)

- Thermal and rolling resistance

Our FEA solutions provide a comprehensive package, including detailed simulations and assessments of tire performance, durability, and safety. Tailored to the needs of tire manufacturers, automotive OEMs, and other industry stakeholders, our services go beyond analysis—we also offer comprehensive FEA training and ongoing support to ensure our clients achieve their goals efficiently and effectively.

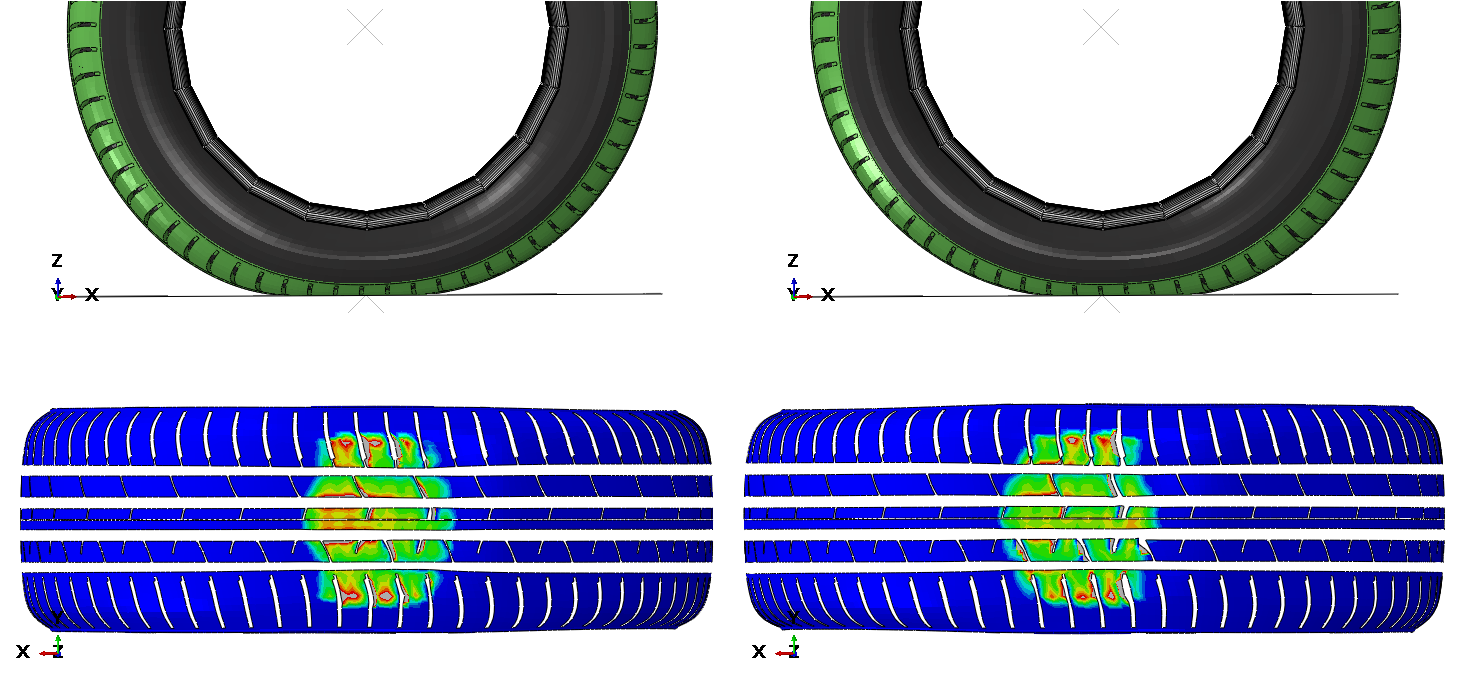

Stress Analysis – Thermal Analysis – Dynamic Analysis

Example of Analysis Capabilities

Optimize. Simulate. Accelerate.

Contact us today for a consultation!

FEA Q&A

What is FEA?

Finite Element Analysis (FEA) is a simulation method engineers use to predict how a tire or other structure will perform under real-world loads and conditions.

How does FEA improve design?

Using FEA early in the design process helps identify and fix potential issues before production begins. This reduces the need for expensive physical prototypes, redesigns, and testing, saving both time and money.

What are the benefits of FEA?

FEA shows failure points, stresses, and deformation, helping manufacturers reduce waste, make products more durable, and create safer, sustainable tire designs.