Digital twin tire Plant

Tailored for Tire Manufacturers

What Is Tire Factory Simulation and Why Digital Twin Technology Matters

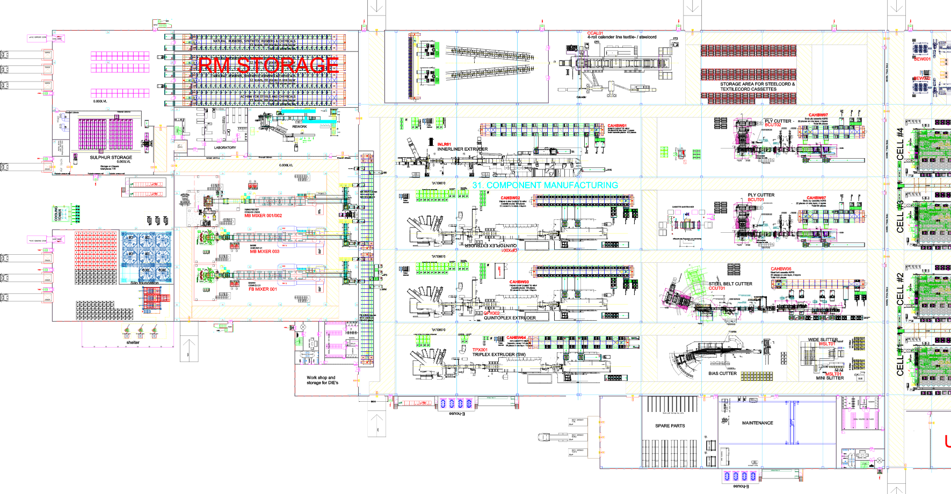

A digital twin tire plant is a virtual model of a tire factory that simulates “what-if” scenarios. It is engineered to optimize tire plant design, processes, machines, and operations, providing highly accurate data analysis and insights. Through simulations, computer models analyze and improve these processes in a virtual environment, offering actionable, data-driven insights that enable manufacturers to simulate every production stage, identify potential bottlenecks or issues, and explore and test innovative design concepts.

At Black Donuts, our simulation technology is specifically designed for the tire industry. We create accurate digital twins of production systems by integrating expert knowledge with precise real-world data and well-justified variables.

Tire Plant Technology | MES & Automation Services | FEA Simulations

Plant simulation benefits

Optimized Production +

Simulate every stage of the manufacturing process to identify inefficiencies and streamline workflows, and enhance process, from raw material handling to final inspection. Suitable for both new tire plants (greenfield) and existing (brownfield) facilities.

Enhanced Quality +

Achieve precision in tire design and construction through detailed virtual modeling. Make safer decisions, refine processes accurately, and meet production goals with consistent high quality.

Sustainable Solutions +

Testing energy-efficient strategies and machinery in virtual scenarios reduces material waste and energy use. Optimize schedules to cut costs and lower emissions, improving energy efficiency and reducing the carbon footprint.

what-if scenarios +

Evaluate materials, equipment and workflows with scenario analysis to enable cost- effective and time-saving decisions.

Identify bottlenecks +

Simulate scenarios to identify bottlenecks, test necessary changes, assess their impact on efficiency, and implement improvements without interrupting production.

Data-Driven Decision +

Leverage real-time and historical data to make accurate, evidence-based decisions, ensuring optimal resource utilization and minimizing inefficiencies.

Increased Flexibility +

Simulations enable rapid adjustments to production parameters, ensuring the plant can respond dynamically to demand, materials, or scheduling changes.

Significant Reduction in Cycle Times +

Digital simulations enable manufacturers to fine-tune processes and identify opportunities to shorten production cycle times, leading to faster time-to-market.

Precision solutions for all tire project needs

Achieve smarter, more efficient, and sustainable production with unmatched precision in simulating all your tire projects

Streamline Costs, Minimize Waste, Optimize Operations

Reduce Footprint

Lower Production & Logistic Costs

Reduce Work-in-Progress

Enhance Layout Optimization

Curious how digital twin technology can improve your layout? Explore our turnkey factory planning approach.

Optimize production flow before construction. Avoid costly errors with predictive simulations.

Contact us today for a consultation!