Understanding Tire Stiffness

The Force Behind Ride, Handling & Safety

Tire stiffness plays a very important but usually overlooked role in the handling, ride, and performance of a vehicle. It directly affects comfort, steering response, braking, cornering, fuel efficiency, and tire wear. Stiffness is direction-dependent and is typically characterized in four types: radial, lateral, longitudinal, and torsional.

- Radial stiffness (vertical compression)

- Longitudinal stiffness (rolling direction)

- Lateral stiffness (side-to-side forces)

- Torsional stiffness (twisting during steering)

Tire Stiffness Types and Real-World Impact

1.Radial Stiffness (Vertical)

What it is: Resistance of the tire compression under vehicle weight in the vertical direction.

Why it matters:

• Ride Comfort: Softer = smoother ride; Stiffer = harsh and noisy

• Load Support: Stiffer tires provide more load support with less deflection

• Handling & Wear: Very soft = slow steering, irregular tread wear

• Fuel Efficiency: Softer tires = higher rolling resistance, lower economy

It affects ride comfort, load-carrying capacity, tread wear, and rolling resistance.

2.Torsional Stiffness

What it is: Resistance to twisting around the vertical axis (during steering).

Why it matters:

• Steering Response: Greater stiffness = quicker, sharper feedback

• Driver Feel: Low stiffness = soggy steering, especially at speed

• Stability: Critical during high-speed lane change or evasive maneuvers

• Safety Systems: Impacts ESC, ABS, and traction control accuracy

It affects steering response, feel, and high-speed stability.

3. Lateral Stiffness

What it is: Resistance to side-to-side (lateral) deformation.

Why it’s important:

• Cornering Grip: Holds shape and hold in turns

• Handling Balance: Impacts understeer/oversteer behavior

• Stability: Improves crosswind and evasive maneuver performance

• Camber Sensitivity: Impacts grip during aggressive cornering

Impacts cornering grip, under/oversteer behavior, and stability.

4. Longitudinal Stiffness

What it is: Deformation resistance in the rolling direction.

Why it’s important:

• Braking: Stiffer = shorter stopping distances

• Acceleration: Better traction, especially under power

• Control Systems: More consistent feedback for ABS and traction control

• Skid Resistance: Soft tires deform more, increasing slip risk

Key to acceleration, braking, and traction.

Challenges Tire Manufacturers Face

Optimizing stiffness is a balancing act. Key challenges include:

1. Trade-Offs Between Performance Goals

- Comfort vs. handling

- Traction vs. durability

- Steering precision vs. high-speed stability

2. Material Constraints

- Eco-materials may compromise stiffness control

- Steel, nylon, or aramid reinforcements impact weight, cost, and stiffness

3. Manufacturing Precision

- Small variations in ply angles or curing can drastically affect stiffness

- Reproducibility across batches is difficult at scale

4. Complex Interdependencies

- Improving one stiffness type can negatively impact others

- Design changes (e.g., sidewall height) influence multiple parameters

5. Simulation vs. Reality

- Models like TMeasy require precise tire parameters

- Real-world conditions (wear, temperature, inflation) are hard to replicate

6. Environmental and Regulatory Pressures

- Need for low rolling resistance tires (fuel efficiency) often conflicts with stiffness targets

- Push for recyclability and bio-based compounds adds uncertainty

7. Application-Specific Demands

- EVs need higher load support and torque resistance

- High-performance tires need lateral/torsional stiffness

- Off-road tires must prioritize flexibility and durability

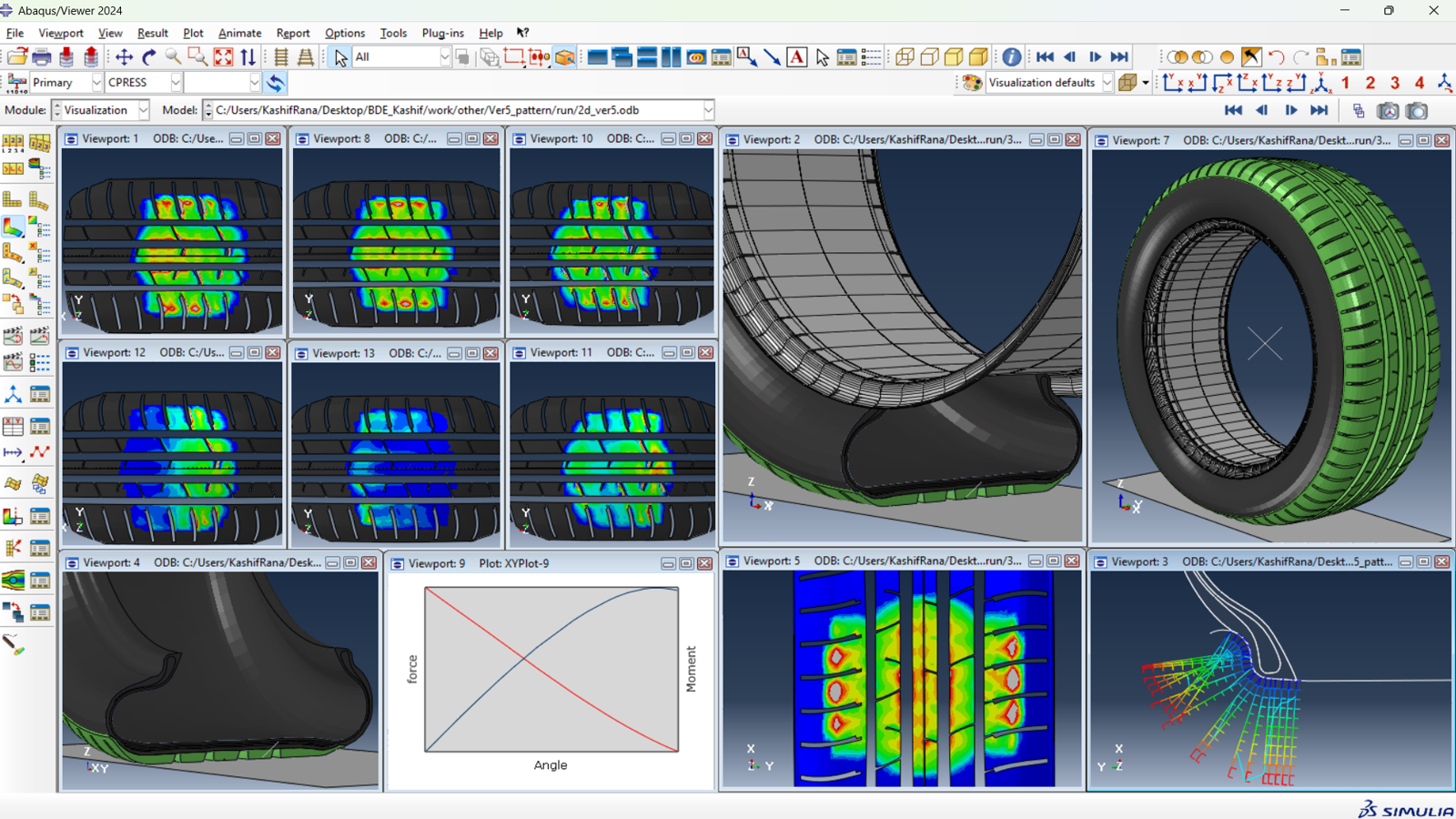

Why FEA Matters

Finite Element Analysis (FEA) is the key to solving these challenges. It allows virtual modeling of stiffness across all directions and driving scenarios, saving time and reducing cost. FEA permits engineers to model the response of a tire to stress, pressure, and motion, before it is built. Virtual prototyping is possible with this tool, and it helps designers optimize stiffness trade-off for performance. for performance.

FEA saves time and money, and it allows manufacturers to optimize tire stiffness for enhanced safety, performance, and efficiency.

Black Donuts and InTire Labs offer end-to-end solutions to master tire stiffness. From early-stage design to final production, BD ensures stiffness properties are precisely tuned to meet safety, comfort, and performance targets—backed by real-world testing and smart simulation. With the right tools and expertise, it can be optimized to meet the growing demands of mobility.

| Challenge | BD’s Solution |

| Stiffness balancing | FEA simulations + multi-objective design optimization |

| Material innovation | InTire Labs’ compound R&D with sustainable and high-performance materials |

| Manufacturing consistency | Turnkey factory setup and tooling precision |

| Accurate modeling | Input-rich tire modeling + real-world test correlation |

| Speed to market | Integrated design-test-production workflow |

| Regulatory demands | Low rolling resistance + safety-compliant design |

| Vehicle-specific needs | Custom tire solutions for EVs, trucks, high-performance & off-road |

Quick Reference Summary

| Stiffness Type | Key Effect | Too Soft → | Too Stiff → |

| Radial | Ride quality, load handling | Floaty feel, poor handling | Harsh ride |

| Torsional | Steering response | Sluggish steering | Sensitive steering |

| Lateral | Cornering & side forces | Poor grip, rollover risk | Harsh cornering, tire chatter |

| Longitudinal | Braking & acceleration | Long stop, poor traction | Harsh contact, skidding |

Tire stiffness is not a one-size-fits-all situation; it is a balancing act. Thanks to the capabilities of FEA simulations and exacting testing, manufacturers can tailor stiffness profiles to the specific needs of each vehicle type and driving condition.