Tire Labelling: The Game Changer Manufacturers Cannot Afford To Miss

In the fast-changing car world, dominated by headlines about electric cars and autonomous vehicles, a quieter yet significant transformation is occurring: tire labelling. Though seemingly minor, this development is reshaping consumer decisions and environmental regulations. But what exactly does tire labelling entail, and why is it becoming an indispensable consideration for manufacturers?

Understanding Tire Labelling

In the early 2000s, tire manufacturers faced a significant public relations crisis when a series of accidents were linked to their tires. Investigations revealed inadequate labelling to inform consumers about tire performance, particularly in wet conditions.

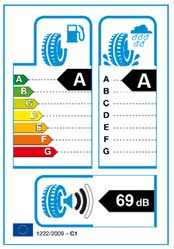

In essence, tire labelling involves grading tires based on rolling resistance, wet grip, and noise levels—providing crucial information to consumers at a glance, similar to energy labels on appliances. Nowadays, the tire labels also include icons for severe snow conditions and icy roads. These labels help consumers make informed choices about tire safety and environmental impact.

The Impact of Tire Labelling

Fuel Efficiency:

One of the primary components of tire labelling is fuel efficiency. Labels include grades ranging from A (most efficient) to G (least efficient), with A-rated tyres potentially reducing fuel consumption by up to 7.5% compared to G-rated ones. This focus on efficiency supports global efforts to mitigate climate change by vehicles’ carbon footprints.

Safety Through Wet Grip Ratings: Safety is paramount. Wet grip ratings, graded from A to G, emphasize safety by indicating the shortest stopping distance in wet conditions. A-rated tires can potentially stop a vehicle up to four car lengths sooner than G-rated ones at 50 mph, prompting manufacturers to invest in advanced materials and tread designs to enhance road safety.

Reducing Noise Pollution: Tire labels address noise pollution by including ratings for external noise levels, ranging from A (quietest) to C (loudest). This encourages manufacturers to design quieter tires, creating a more comfortable urban environment.

Regulatory Landscape and Future Directions

The EU’s tire labelling regulation, implemented in 2012, has been instrumental in driving innovations in tire technology. By 2020, it helped reduce energy consumption by up to 45 TWh annually and cut around 15 million tonnes of CO2 emissions. Additionally, upcoming regulations will incorporate testing for tire wear, scheduled to commence in 2024 as part of broader EU emissions standards.

In terms of tires and tire wear, the regulation is expected to come into force from 1 July 2028 for new tire types of class C1; from 1 April 2030 for new tire types of class C2 and from 1 April 2032 for new tire types of class C3. The test for C1 tires (for cars and other light vehicles) has now entered into force from February 2024 as part of the Working Party on Noise and Tyres (Groupe Rapporteur Bruit et Pneumatiques – GRBP) and will almost certainly be adopted by the official WP 29 by June 2024. It will become mandatory on new tires launched after January 2025 and all existing tires by June 2026. (Global Tire Intelligence, March 2024)

The Ripple Effect

The implications of tire labelling extend far beyond the immediate concerns of fuel efficiency, safety, and noise. They signal a shift in how automotive manufacturers approach design and production. This system incentivizes sustainability and innovation, encouraging manufacturers to rethink materials, processes, and the overall lifecycle of their products. This move aligns with increasing consumer demand for environmentally friendly and safe products, potentially reshaping market dynamics and consumer preferences.

Furthermore, tire labelling opens up a dialogue about transparency and information in the automotive industry. Providing consumers with clear, easily understandable data empowers them to make informed decisions based on values that matter to them, whether that’s environmental impact, safety, or cost savings.

The Role of Manufacturers and Innovations by Black Donuts

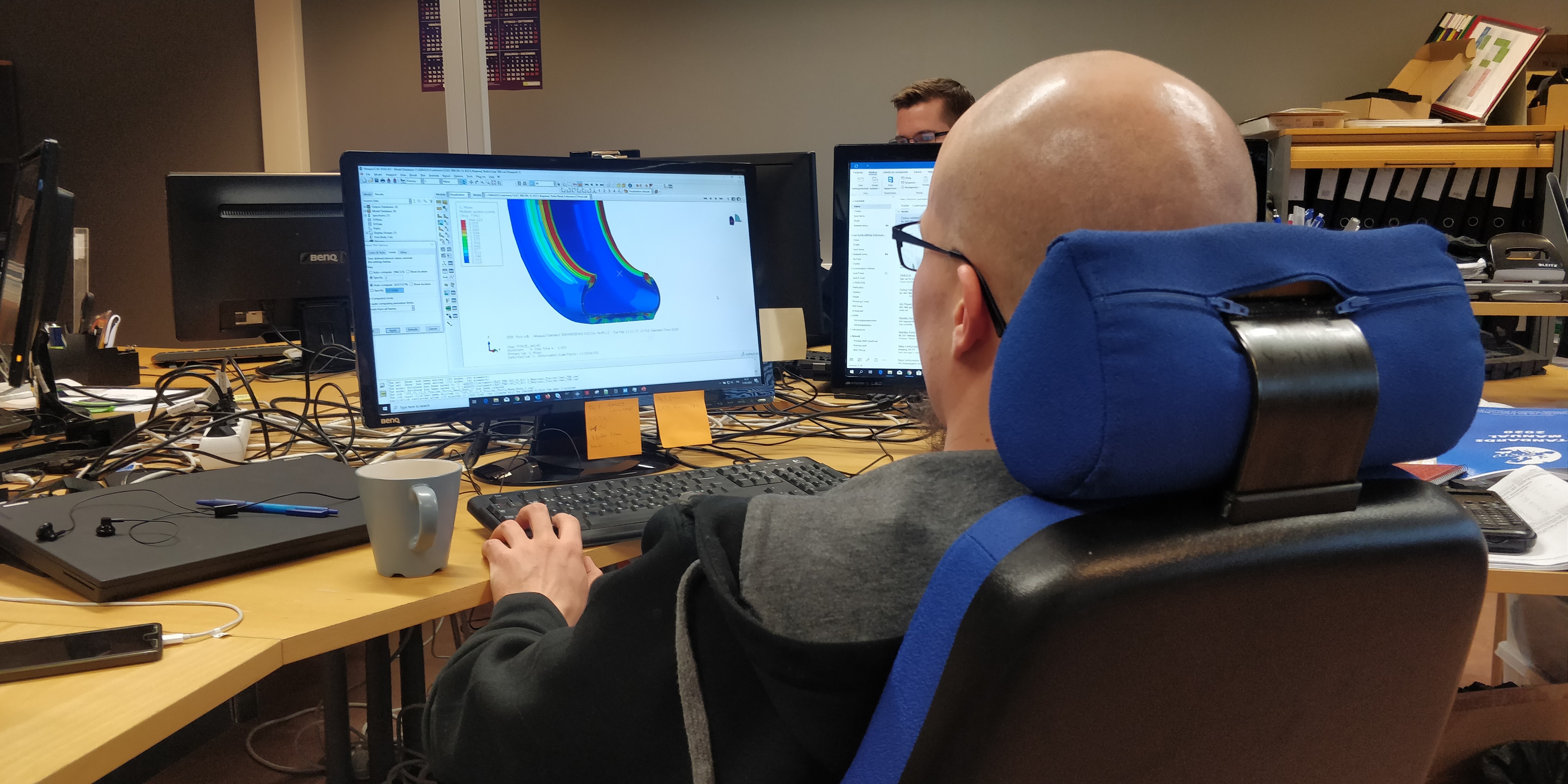

Black Donuts has been addressing tire development challenges related to tire labelling since its launch. In recent years, even more R&D efforts and innovations by Black Donuts have been gathered together to deliver winning solutions to get top-labelled tyres.

Thanks to innovative materials used in tread compounding, Black Donuts has introduced even more high-performing solutions for wet grip and rolling resistance. Furthermore, our long-term, in-depth research on tire noise is starting to produce its first results, with the introduction of increasingly silent tires to the market.

The Road Ahead

Regulatory frameworks worldwide are experiencing significant transformations aimed at enhancing safety and transparency within the tire industry. From Europe’s rigorous tire labelling regulations to emerging standards in expanding markets, adherence is no longer discretionary—it’s imperative.

Tire labelling, a seemingly simple measure, carries profound implications for sustainability, safety, and consumer rights. It’s not a trend to be ignored by manufacturers—it’s a game-changer. As the industry evolves, the focus shifts from adaptation to leadership.

As we look to the future, the significance of tire labelling is only set to increase. With advancements in technology and materials, the potential for even more efficient, safer, and quieter tires is vast. For manufacturers, staying ahead in this game means investing in innovation and sustainability – areas that are becoming non-negotiable in the eyes of consumers and regulators alike. In addition, it allows them to comply with standards while distinguishing their products in a competitive market.

Source: Europa.EU, Merityre.co.uk, ec., International Organization for Standardization (ISO), Black Donuts Engineering Inc., Global Tire Intelligence, March 2024